Machanical Engineers (Oil & Gas, Pressure Vessels) All About Machanical Engineering

Monday 31 October 2016

Skid Mounted LPG Station

1) Minimum Installation Area.

2) Low Investments and low maintenance Cost.

3) Transportable, compact system on the Skid.

4) Ex-proof electrical execution.

5) Safety execution included.

6) Possibility to compose the system as complete unit with all required safety fittings.

7) Additionally available with Autogas filling station.

1) Delivered product : LPG

2) Temperature range : -15℃ ~ 40℃

3) Design pressure : 1.8MPa

4) Flow rate : depending on the type of pump installed

5) Tension : 380V / 50Hz, 220V / 50Hz

|

| Skid Mounted LPG Station |

|

| Skid Mounted LPG Station |

Saturday 29 October 2016

Specific Gravity Table

Types of Heat Exchangers

Friday 28 October 2016

Welding Consumable Calculation

click here to dowload -- >> Welding Consumable Calculation

How to download --> click on link wait 5 Sec then click on SKIP AD

Monday 24 October 2016

Painting Defects

PAINT FAULTS, BITTINESS

Inclusions,

either airborne or from the paint itself.could be partially cured paint, out of

shelf life.

|

| BITTINESS |

Thursday 20 October 2016

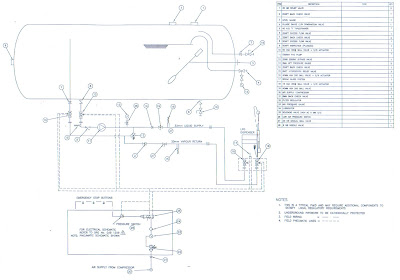

LPG AutoGas Station Installation Drawing, Design

Autogas is the common name

for liquefied petroleum gas (LPG) when it is used as a fuel in internal

combustion engines invehicles as well

as in stationary applications such as generators. It is a

mixture of propane and butane.

Autogas is widely

used as a "green" fuel, as its use reduces CO2 exhaust

emissions by around

15% compared to petrol. One litre of petrol produces 2.3 kg of CO2 when burnt, whereas

the equivalent amount of autogas (1.33 litre due to lower density of autogas)

produces only 1.5 * 1.33 = 2 kg of CO2 when burnt. It has an octane rating (MON/RON)

that is between 90 and 110 and an energy content (higher heating value—HHV)

that is between 25.5 megajoules per litre (for pure propane) and

28.7 megajoules per litre (for pure butane) depending upon the actual fuel

composition.

Autogas is the third

most popular automotive fuel in the world, with approximately 16 million of 600

million passenger cars powered using the fuel, representing less than 3% of the

total market share. Approximately half of all autogas-fueled passenger vehicles

are in the five largest markets (in descending order): Turkey, South Korea,

Poland, Italy, and Australia.

IN PAKISTAN

LPG was allowed to be used

as an automotive fuel in 2005 and first Autogas station became operative in

2010 located at Sialkot. Uptill 2014 there were only four Autogas stations

operating in Pakistan serving around 1000 vehicles. LPG failed to attract

attention of the investors and customers due to extremely cheap prices of CNG

as Pakistan had huge Natural Gas reserves. Pakistan in a decade became the

largest consumer of CNG. This impacted Pakistan's reserves in a negative way

and they receded in a quick span. In November 2013 Oil and Gas Regulatory

Authority issued about 40 NoC's for setting up LPG Autogas stations mainly to

PSO, a State owned Petroleum giant. However, in December 2013 Oil and Gas

Regulatory Authority (OGRA) contrary to the rest of the world where LPG is

promoted, declared LPG a risk to public safety thus banned LPG to be used in

Public transport vehicles, thus closing the era of LPG in Pakistan even before

it started.

LPG AutoGas Station Installation Drawing, Design

|

| LPG AUTOGAS STATION |

|

UNDERGROUND LPG SYSTEM PROCESS AND INSTRUMENTATION DIAGRAM

|

|

| BOQ (UNDERGROUND LPG SYSTEM PROCESS AND INSTRUMENTATION DIAGRAM) |

|

ABOVEGROUND LPG SYSTEM PROCESS AND INSTRUMENTATION DIAGRAM

|

|

| LPG AUTO GAS STATION INSTRUMENTATION PART LIST |

Characteristics of LPG

- LPG – Liquefied Petroleum Gas

- Mixture of Propane & Butane (95/5)

- Heavier than air

- Ignition temperature of LPG is 450 0C

Benefits of LPG

- Re-fuelling time in vehicle is similar to petrol

- Vehicle conversion is significantly economical than CNG

- 20 kg LPG gives around 350 to 400 km run.

Why use LPG?

Unavailability of CNG and continuous increase in petrol & diesel prices invoke the need of cheaper alternative fuel.

ASME Certificates Offered

Power Boilers

Section I

Section I

·

S - Power Boilers

·

A - Assembly of Power Boilers

·

E - Electric Boilers

·

M - Miniature Boiler

·

PP - Pressure Piping

·

V - Boiler Pressure Relief Valves

·

PRT - Parts Fabrication

Heating Boilers

Section IV

Section IV

·

H - Heating Boilers/Cast Iron Sectional Heating Boiler

·

HLW - Lined Potable Water Heaters

·

HV - Heating Boiler Safety Valves

·

PRT - Parts Fabrication

Pressure Vessels

Section VIII Division 1

Section VIII Division 1

·

U - Pressure Vessels

·

UM - Miniature Pressure Vessels

·

UV - Pressure Vessel Pressure Relief Valves

·

UD - Pressure Vessel Pressure Relief Devices

Pressure Vessels

Section VIII Division 2

Section VIII Division 2

·

U2 - Pressure Vessels (Alternative Rules for Pressure Vessels)

Pressure Vessels

Section VIII Division 3

Section VIII Division 3

·

U3 - High Pressure Vessels

·

UV3 - High Pressure Vessel Pressure Relief Valves

·

UD3 - High Pressure Vessel Pressure Relief Devices

Reinforced Plastic Vessels

Section X

Section X

·

RP - Fiber-Reinforced Plastic Vessels

Transports Tank

Section XII

Section XII

·

T - Transport Tanks

·

TV - Transport Tanks Pressure Relief Valves

·

TD - Transport Tanks Pressure Relief Devices

·

PRT - Parts Fabrication

Wednesday 19 October 2016

DESIGN OF PRESSURE VESSEL TO CODE SPECIFICATION

American, Indian, British, Japanese,

German and many other codes are available for design of pressure vessels.

However the internationally accepted pressure vessel code is American Society

Of Mechanical Engineers (ASME).

Various codes governing the procedures for the design for fabrication,

inspection, testing, and operation of pressure vessels have been developed,

partly as a safety measure. These procedure furnish standards by which, any

state can be assured of the safety of the pressure vessel installed within its

boundaries. The code used for unfired pressure vessel is section 8 of the ASME

boiler and pressure vessel code. It is usually necessary that the pressure

vessel equipment be designed to a specific code in order to obtain insurances

on the plant in which the vessel is to be used. Regardless of the method of

design, pressure vessels within the limits of the ASME code specifications are

usually checked against the specifications.

DEVELOPMENT AND SCOPE OF ASME CODE

In 1911, American society of mechanical engineers, established a committee to formulate standard specifications for the construction of steam boilers and other pressure vessels. This committee reviewed the existing Massachusetts and Ohio rules and conducted an extensive survey among superintends of inspecting departments, Engineers, fabricators and boiler operators. A number of preliminary reports were issued and revised. A final draft was prepared in 1914 and was approved as a code and copyrighted in 1915.

The introduction to the code started that public hearings on the code should be held every two years. In 1918, a revised edition of the ASME code was issued in 1924,the code was revised with the addition of the new section 8, which represented a new code for unfired pressure vessels.

THE API-ASME CODE

In 1931 a joint API-ASME committee on unfired pressure vessels was appointed to prepare a code for safe practice in the design, construction, inspection and repair of unfired pressure vessels.

SELECTION OF THE TYPE OF VESSEL

The first step in the design of any vessel is the selection of the type best suited for the particular service in question. The factors influencing this choice are:

1. The operating temperature and pressure.

2. Function and location of the vessel.

3. Nature of the fluid.

4. Necessary volume for storage or capacity for processing.

It is possible to indicate some generalities in the existing use of the common type of vessels. For storage of fluids at atmospheric pressure, cylindrical tanks with flat bottoms and conical roofs are commonly used. Spheres or spheroids are employed for pressure storage where the volume required is large. For smaller volume under pressure cylindrical tanks with formed heads are more economical

TYPE OF VESSELS

OPEN VESSELS

Open vessels are commonly used as urge tanks between operations , as vats for batch operations where materials may be mixed and blended as setting tanks, decanters, chemical reactors, reservoirs and s on. Obviously this type of vessel is cheaper than covered or closed vessel of the same capacity and construction. The decision as to whether or not open vessels may be used depends upon the fluid to be handled and the operation.

CLOSED VESSELS

Combustible fluids, fluids emitting toxic or obnoxious fumes and gases must not be stored in closed vessels. Dangerous chemicals such as caustic are less hazardous if stored in closed vessel. The combustible nature of petroleum and its products associates the use of closed vessels and tanks throughout the petroleum and petrochemical industries. Tanks used for the storage of crude oils and petroleum products and generally designed and constructed as per API specification for weld a silo storage tanks.

CYLINDRICAL VESSEL WITH FLAT BOTTOMS AND CONICAL OR DOMED ROOFS

The most economical design for a closed vessel operating of atmospheric pressure is the vertical cylindrical tank with a conical roof and a flat bottom resting directly on the bearing soil of the foundation composed by sand, gravel or crushed rock. In case where it is desirable to use a gravity feed, the tank is raised above the ground, and the flat bottom may be supported by columns and wooden joints or steel beams.

CYLINDRICAL VESSELS WITH FORMED ENDS

DEVELOPMENT AND SCOPE OF ASME CODE

In 1911, American society of mechanical engineers, established a committee to formulate standard specifications for the construction of steam boilers and other pressure vessels. This committee reviewed the existing Massachusetts and Ohio rules and conducted an extensive survey among superintends of inspecting departments, Engineers, fabricators and boiler operators. A number of preliminary reports were issued and revised. A final draft was prepared in 1914 and was approved as a code and copyrighted in 1915.

The introduction to the code started that public hearings on the code should be held every two years. In 1918, a revised edition of the ASME code was issued in 1924,the code was revised with the addition of the new section 8, which represented a new code for unfired pressure vessels.

THE API-ASME CODE

In 1931 a joint API-ASME committee on unfired pressure vessels was appointed to prepare a code for safe practice in the design, construction, inspection and repair of unfired pressure vessels.

SELECTION OF THE TYPE OF VESSEL

The first step in the design of any vessel is the selection of the type best suited for the particular service in question. The factors influencing this choice are:

1. The operating temperature and pressure.

2. Function and location of the vessel.

3. Nature of the fluid.

4. Necessary volume for storage or capacity for processing.

It is possible to indicate some generalities in the existing use of the common type of vessels. For storage of fluids at atmospheric pressure, cylindrical tanks with flat bottoms and conical roofs are commonly used. Spheres or spheroids are employed for pressure storage where the volume required is large. For smaller volume under pressure cylindrical tanks with formed heads are more economical

TYPE OF VESSELS

OPEN VESSELS

Open vessels are commonly used as urge tanks between operations , as vats for batch operations where materials may be mixed and blended as setting tanks, decanters, chemical reactors, reservoirs and s on. Obviously this type of vessel is cheaper than covered or closed vessel of the same capacity and construction. The decision as to whether or not open vessels may be used depends upon the fluid to be handled and the operation.

CLOSED VESSELS

Combustible fluids, fluids emitting toxic or obnoxious fumes and gases must not be stored in closed vessels. Dangerous chemicals such as caustic are less hazardous if stored in closed vessel. The combustible nature of petroleum and its products associates the use of closed vessels and tanks throughout the petroleum and petrochemical industries. Tanks used for the storage of crude oils and petroleum products and generally designed and constructed as per API specification for weld a silo storage tanks.

CYLINDRICAL VESSEL WITH FLAT BOTTOMS AND CONICAL OR DOMED ROOFS

The most economical design for a closed vessel operating of atmospheric pressure is the vertical cylindrical tank with a conical roof and a flat bottom resting directly on the bearing soil of the foundation composed by sand, gravel or crushed rock. In case where it is desirable to use a gravity feed, the tank is raised above the ground, and the flat bottom may be supported by columns and wooden joints or steel beams.

CYLINDRICAL VESSELS WITH FORMED ENDS

Closed cylindrical vessels with formed heads on both sides used where the vapour pressure of the stored liquid may dictate a stronger design , codes are developed through the efforts of the American petroleum institute and the ASME to govern the design of such vessels . These vessels are usually less than 12 feet in diameter. If a large quantity of liquid is to be stored, a battery of vessels may be used.

SPHERICAL AND MODIFIED SPHERICAL VESSELS

Storage containers of large volumes under moderate pressure are usually fabricated in the shape of a sphere or spheroid. Capacities and pressures used in this type of vessel vary greatly for a given mass; the spherical type of tank is more economical for large volume, low pressure storage operation..

VERTICAL vs HORIZONTAL VESSELS

In general functional requirements determine whether the vessel shall be vertical or horizontal. e.g.: distilling columns, packed towers which utilize gravity require vertical installation.

Heat exchangers and storage vessels are either horizontal or vertical. If the vessel to be installed outdoor wind loads etc are to be calculated to prevent overturning, thus horizontal is more economical. However floor space, ground area and maintenance requirements should be considered.

THANKS,

Monday 17 October 2016

Welding And Its Classification

Welding:

Welding is a process of joining

two metal pieces by the application of heat. Welding is the least expensive

process and widely used now a days in fabrication. Welding joints different

metals with the help of a number of processes in which heat is supplied either

electrically or by mean of a gas torch. Different welding processes are used in

the manufacturing of Auto mobiles bodies, structural work, tanks, and general

machine repair work. In the industries , welding is used in refineries and pipe

line fabrication. It may be called a secondary manufacturing process.

Classification of welding

processes:

There are about 35 different

welding and brazing process and several soldering methods, in use by the

industry today. There are various ways of classifying the welding for example,

they may be classified on the basis of source of heat(flames ,arc etc.)

In general various welding

processes are classified as follows.

1: Gas Welding

(a): Air Acetylene

(b): Oxy Acetylene

(c): Oxy Hydrogen Welding

2: Arc Welding

(a): Carbon Arc welding

(b); Plasma Arc welding

(c): Shield Metal Arc Welding

(d): T.I.G. ( Tungsten Inert

Gas Welding)

(e): M.I.G. ( Metal Inert Gas

Welding)

3: Resistance Welding:

(a): Spot welding

(b): Seam welding

(c): Projection welding

(d): Resistance Butt welding

(e): Flash Butt welding

4: Solid State Welding:

(a): Cold welding

(b): Diffusion welding

(c): Forge welding

(d): Fabrication welding

(e): Hot pressure welding

(f): Roll welding

5: Thermo Chemical Welding

(a): Thermit welding

(b): Atomic welding

6: Radiant Energy Welding

(a): Electric Beam Welding

(b): Laser Beam Welding

Welding Joints

Different types of welding

joints are classified as Butt, Lap , Corner, Tee and edge joints which are

shown in figure

Thursday 13 October 2016

ASME B40.100 Pressure Gauges and Gauge Attachments

ASME B40.100 Pressure Gauges and Gauge Attachments

or

ASME B40.100 Pressure Gauges and Gauge Attachments

How to download --> click on link wait 5 Sec then click on SKIP AD

Machanical Engineers (Oil & Gas, Pressure Vessels)

Facebook Page (Pressure Vessel Design)

Subscribe to:

Posts (Atom)